Cal & logs attached.

So I when I built my new loom I added Flex Fuel to the mix because it's actually available here and our 'premium' 91 octane is not so much so well, why not. It ran great from the time I started messing until I pulled the sensor out last autumn in preparation to get the car refereed. This engine really likes E85, it takes an extra bit of timing, just generally runs better, and my piston tops looked just about brand new again. Even sounds rowdier. My $/mile are also slightly less with straight E85 (~80% year round here). It's been a win all around.

I got through with that in referee thing in August, been getting my fun parts back on the car. But the ethanol sensor is giving me fits. Last year it was rock solid.

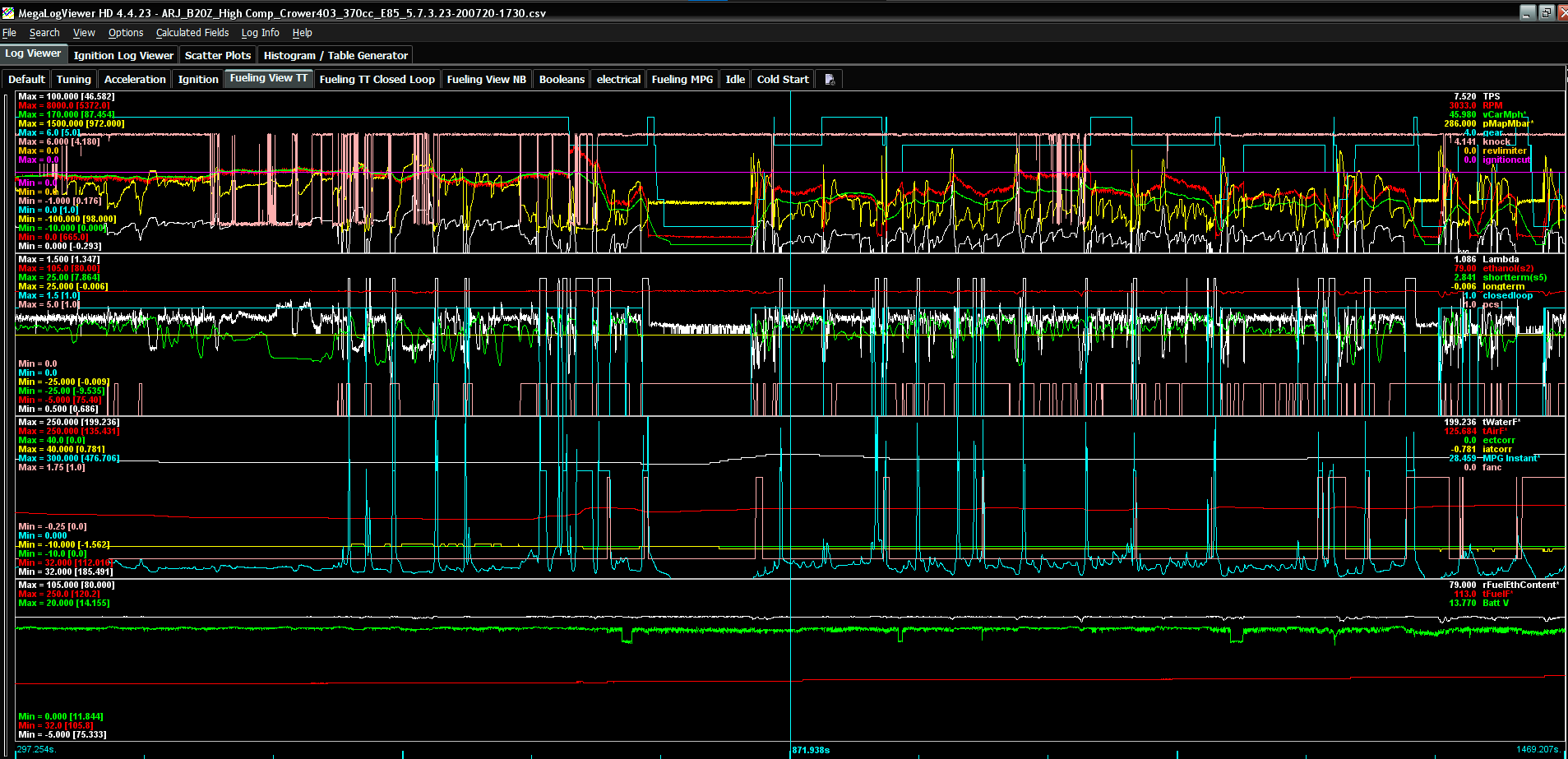

Ethanol content would only change when I filled up and/or changed mixes, never dithered more than a % or two during a tank. White trace, bottom graph:

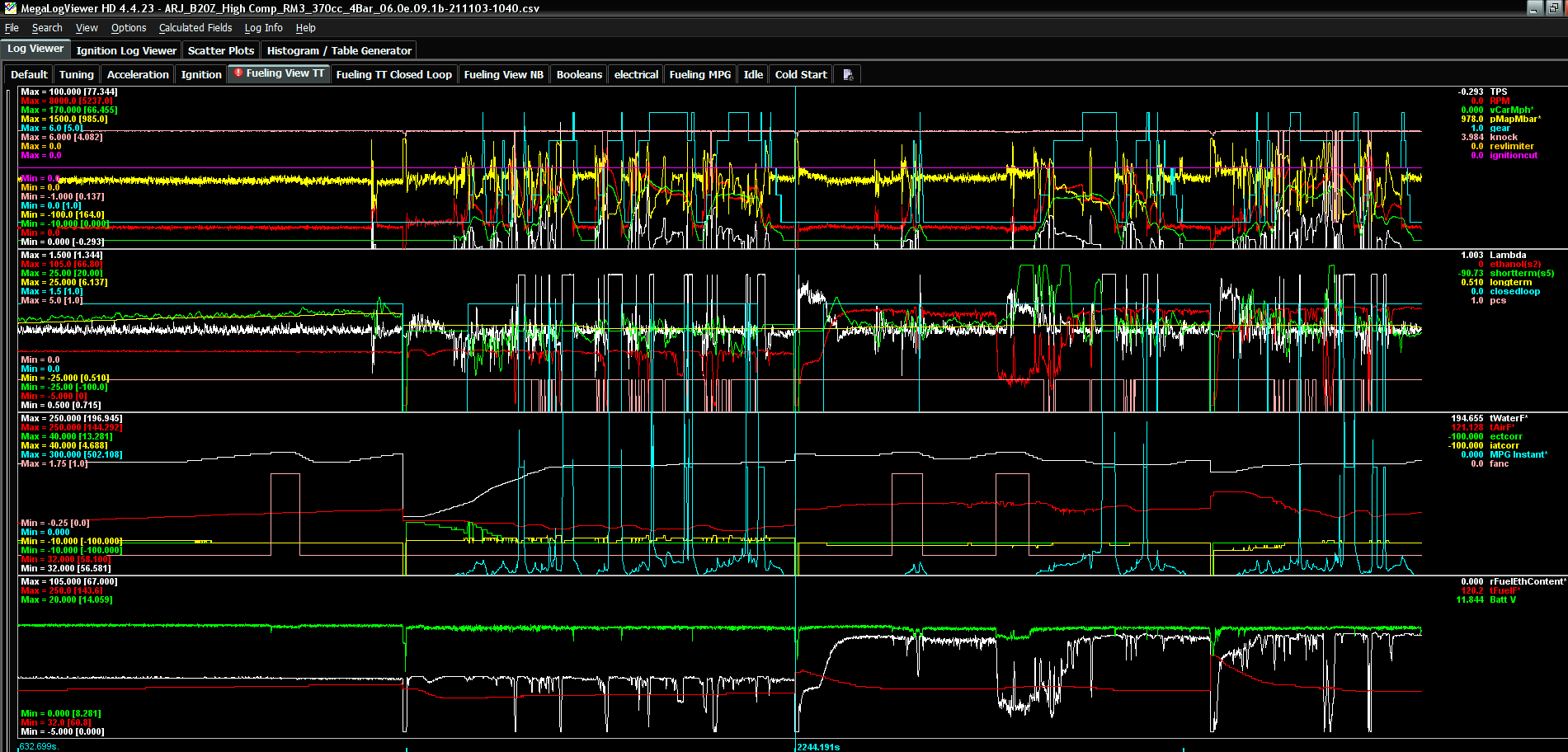

Now it's got these dropouts. It makes the Hondata flex fuel unusable:

** Note, that is a combo of three logs and there is a gas stop for a couple more gallons of E85 in the middle, at the cursor.

When I first reinstalled the sensor, it was obviously still full of regular old 91 octane E10. I noticed all of the dithering and, assuming my sensor had crapped out, got another one from the Chevy dealer and swapped it out to no avail.

I noticed comparing back to logs from last year that my ECU battery voltage was lower than last year. Since then I have found and addressed a couple of issues:

- Trans ground had a small voltage drop so I made a new one.

- Alternator feed was damaged at some point so I made a new one.

These two fixes got my running voltage back up to a normal range.

I have also done the following to test:

- Checked pullup resistor. It's a 2.4kOhm resistor as spec'd by Hondata, reads ~2.3kOhm with DVOM. It's the exact Vishay part they spec in the help and built in to the engine loom near the sensor.

- Confirmed full power to the sensor. It's on fuse 15 and has no voltage drop to the sensor.

- Voltage drop test of sensor's ground = 0 to thermostat ground. Only other component that shares this ground is the power steering pressure switch and that's a no load sink straight to the thermostat ground anyway.

- Back-probed at ECU connector and, using the DVOM in frequency mode confirmed that the S300 is spitting out the same ethanol content number as the sensor is sending in Hz.

- Reverted my return line to a straight -6 hose from the bottom of the sensor to the hard line at the firewall. I had installed a Jiffy-Tite quick disconnect at the hard line since it's tough to get two hands and two wrenches down there, but thought that maybe the shorter section of hose might have been putting some bending stress on the sensor. Also wanted to make everything was exactly as it was when things were working correctly.

- Bench tested both of my sensors and dry tested them on the car.

- Sighting down the tubes on the sensors, I can see the element is intact and not damaged or touching the sides of the tube in any way (except the mount, obviously)

So yeah, everything is back where it was before and I'm out of ideas.

When I cold start the car, ethanol content is rock solid, just like I expect. As the car warms up and starts to closed-loop control, I'm confident that the ethanol readings are good because the fuel trim stays nice and calm. If I go out and start to drive, it's still okay while the car is cool but seems to go haywire as things heat soak. Once hot, it starts to show dropouts as I load the engine (This is why I went back to a longer, softer return line, in case the shorter one was bending the sensor around as the engine moved). Once really well heat soaked, it's all over the place but still generally reads much higher under light loads but the magnitude of the dropouts becomes worse. Fuel temperature always reads rock solid and similar to IAT, which is expected.

Even while on E10, before I really started digging in to diagnosis, I took it on a canyon run and it was just flatlined at 0% by the time I got back to the freeway.

- I don't have evidence to suggest an issue with the S300. The DVOM tests are showing me the same content and the same dropouts that the S300 is reporting.

- I have no reason to believe I am 'starving' the fuel return line and running bubbles across the sensor, as other people have reported.

- I really don't have evidence to suggest a wiring issue either. I've gone over everything with a pretty fine toothed comb at this point. Again, the signal frequency at the sensor connector is exactly the same as what the ECU is reporting.

- If it was an electrical noise issue I would expect it to be there all the time, not seeming temperature-correlated.

Anyone got any ideas, or run into this failure before?

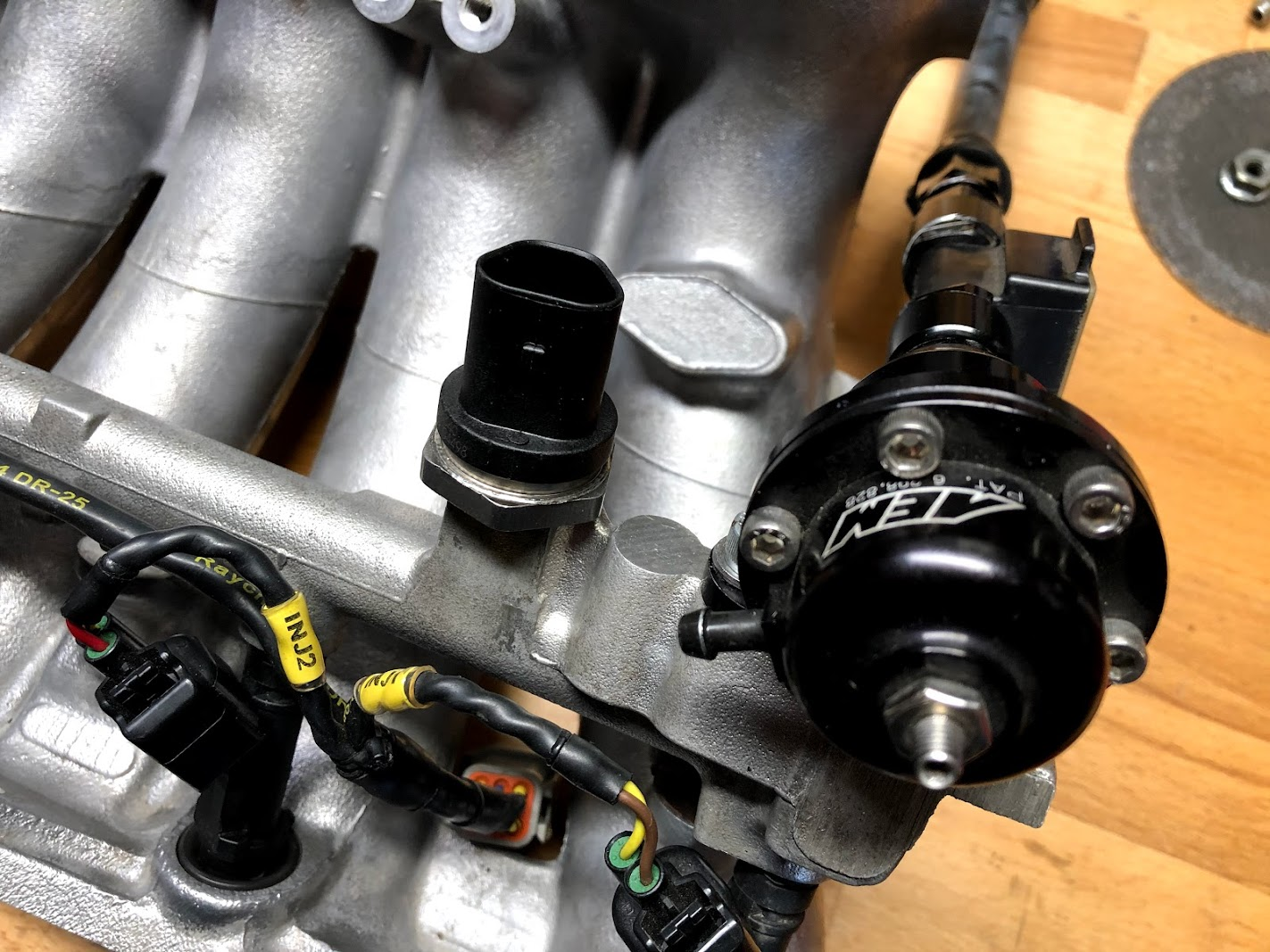

For reference, the sensor is mounted directly to the regulator outlet. Crappy angle on this photo, but you get the idea: